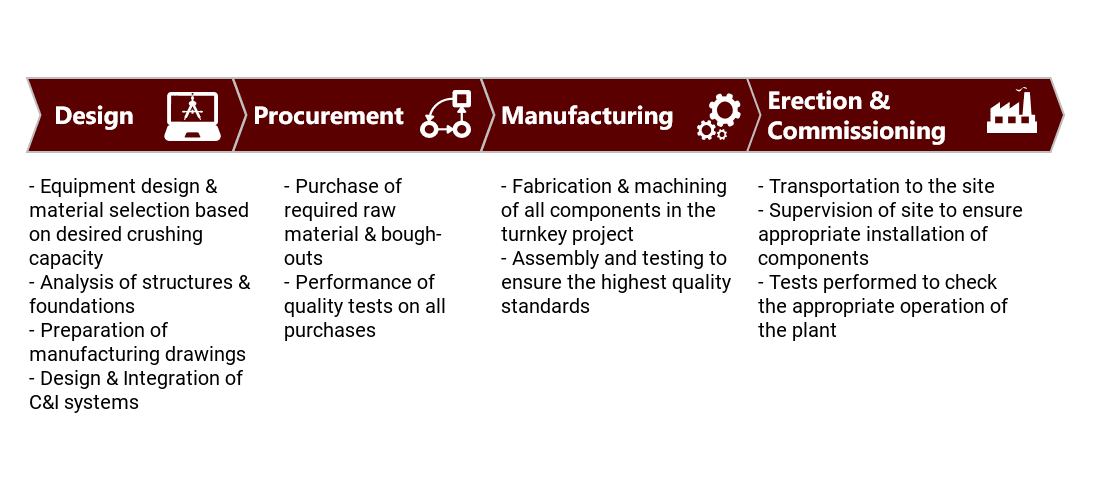

Worldwide there is a clear need for a holistic approach to industrial sugar production, from sugar cane & beet plantations, to sugar plant design, manufacture and operation. That is why during the last decades we have developed a team with wide experience in all the fields necessary to successfully develop sugar cane & beet anywhere in the world. Kay Bouvet has capabilities to execute sugar projects up to 30,000 TCD (tonnes crushed per day) on an EPC basis, right from concept to commissioning. Our projects span the range of engineering activities from design and manufacturing of heat exchangers, boilers, pressure vessels, associated piping, conveyor systems and structures, to control and instrumentation.

Kay Bouvet Engineering has executed numerous turnkey sugar projects across India over the last 20 years, including co-generation power plants and ethanol distilleries:

Kay Bouvet also has a long experience in expansion and modernization projects on an EPC basis across India and internationally. We have also commissioned various co-generation power plants, mill houses and boiling houses on an EPC basis.

Summary of recent EPC projects:

We collaborate with the market leading corporations in the sugar industry in India, such as Rana Sugars, Bajaj Hindustan & GMR Industries. We also collaborate with leading groups worldwide for the development of turnkey sugar plants around the world.

With over 40,000m2 of workshop, 3 manufacturing units, and single piece handling capacity of up to 200 Tons, our workshops are up to the task of producing some of the biggest equipment in the industry.

It is not only in size that our workshop excels, but also in precision. We own the latest machinery imported from Europe's best machine producers, mainly from Germany. It is thanks to this machinery and our specialized team of engineers operating them that we are able to manufacture specialized equipment to the requirements of our esteemed clients.

We have received numerous international certifications that qualify us for the manufacturing of specialized equipment:

Moreover, the Nuclear Power Corporation of India (NPCIL) has recently qualified us as an EPC contractor for the supply of a Waste Management & Heavy Water Upgradation plant, an achievement that highlights not only our high grade manufacturing capabilities but also our management excellence, a prerequisite for such a large scale project.